Single-screw extruder gearboxes are designed for splash lubrication. The quantity of oil ensures that all gears and bearings are lubricated. An oil level indicator shows the oil level. In the event that the nominal power exceeds the thermal limit power, an integrated water cooling coil could be installed. For special applications an external cooling and lubrication unit could be applied.

Twin shaft extruder gearboxes are equipped with a combined splash- and pressure feed lubrication. An electrical or mechanical oil pump ensures that all gears and bearings are sufficient lubricated. In the small and middle power range, the gearbox housing is used as an oil reservoir.

The series TPM 2 DOS and TPM 3 are by default equipped with an oil pump and filter.

For the other series the cooling unit is not included by default, but could be ordered optionally.

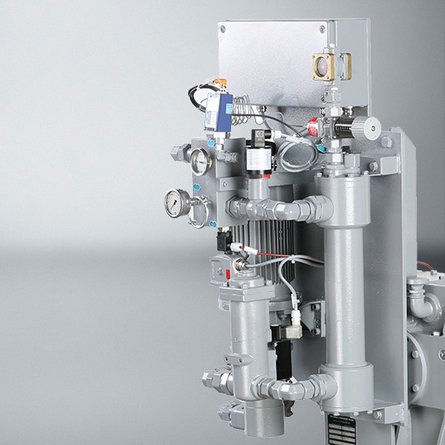

Our tailor made oil cooling and lubrication units ensure optimum lubrication of our DURUMAX® gearboxes and an efficient heat elimination in every range of performance.

Outstanding Features:

- For every application is an optimal dimensioned oil cooling and lubrication unit available

- Wide range of standard units consisting of

> Electrical driven oil pump

> Heat-exchanger

> Pressure switch

> Oil-filter

Optional features:

- Switchable double oil filter with impurification display

- Thermometer, manometer

- Thermostat valve for cooling water flow

Contact

Stefan Knieling

TS Henschel GmbH

Tel.: +49 561 810495-21

Fax: +49 561 810495-95

E-Mail: knieling.stefan(at)henschel.de