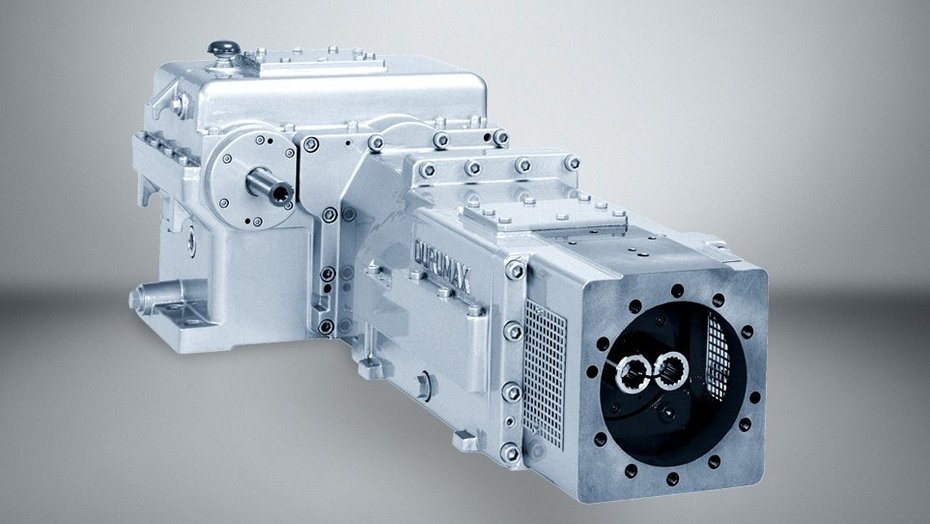

The DURUMAX® TPM 3 DOS-V extruder gearbox of Henschel Antriebstechnik offers the extrusion manufacturer high technology on the newest state of the art technology. In the global market the TPM 3 DOS-V has asserted itself against the hardest competition and is meanwhile the most widely used counter-rotating extruder gearbox.

Outstanding Characteristics:

- High "power density" with all used center distances

- Modular and suitable design

- High efficiency by reduction of the rotary parts

- Exceptionally high operational safety

- Torque ratings determined by the customers and market requirements

- Excellent price-performance ratio

The technical concept of the TPM 3 DOS-V series consists of a reduction gearbox and a distribution gearbox. Both gearbox modules are connected by the thrust bearing housing.

In contrast to the TPM 3 series the distribution of the torque occurs with the DOS gears in the distribution step with two pairs of gears like a double helical gear.

The gearbox can be driven directly by a motor or with a belt at the Input shaft. In the multi-stage helical gearbox, the speed is reduced and the required torque is created. This torque is transmitted in the distribution gearbox to the two counter-rotating output shafts.

The axial forces resulting from the extrusion process are absorbed by thrust bearings inside the thrust bearing housing.

Contact

Stefan Knieling

TS Henschel GmbH

Tel.: +49 561 810495-21

Fax: +49 561 810495-95

E-Mail: knieling.stefan(at)henschel.de